The Rise of Sushi Robots: Transforming Restaurant Efficiency

Sushi is a popular dish known for its fresh ingredients and skilled preparation. However, as more people enjoy sushi, restaurants are turning to technology to keep up with demand. Robot sushi machines are helping restaurants make sushi faster and more consistently than ever before. These robots are changing how sushi is made, making it easier for restaurants to serve high-quality sushi quickly while still meeting customer expectations. In this article, we’ll explore how sushi is changing in the sushi restaurant.

History of Sushi and the Path to Automation

Originally, sushi began as narezushi, a method of fermenting fish with rice to preserve it. By the Edo period (1600s), sushi took a more recognisable form, nigiri, where fresh fish was placed on top of vinegared rice and served quickly as a street food in Tokyo (then Edo).

Automation in sushi production started gaining traction in the mid-20th century. The breakthrough came with the invention of kaiten-zushi (conveyor belt sushi) in 1958 by Yoshiaki Shiraishi. Inspired by a beer-bottling conveyor belt, Shiraishi sought to streamline sushi service using similar technology, making it affordable and accessible. This innovation revolutionised the industry, reducing labour costs and making sushi more affordable while maintaining rapid customer turnover?.

The move to automation continued. Sushi-making machines were developed to handle the time-consuming tasks of rolling and shaping sushi. Today, restaurants use robots and advanced machines to meet high-volume demands accurately and efficiently.

Types of Robotic Sushi Machine

There are two primary types of sushi: Nigiri and Makizushi. Both are widely enjoyed by people in Japan and around the world. Each type of sushi requires a different kind of machine for efficient production. Below is an overview of these sushi varieties and their corresponding machines.

-

Maki Sushi Machine

Makizushi, or rolled sushi, is usually wrapped in seaweed and filled with cucumber, fried egg, and other fillings. A variation is uramaki, where the rice is outside the seaweed.

A Maki Sushi Machine is made to create maki and uramaki rolls accurately. The machine ensures the rice is evenly distributed, allowing different thicknesses and densities to match different preferences.

Simply add the sushi rice, seaweed, and fillings, and let the machine do the rest. In as little as 15 seconds, it produces a perfect sushi roll suitable for both home and commercial kitchens.

-

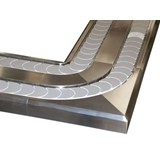

Nigiri Sushi Machine

Nigiri sushi is a popular small rice ball topped with fish or other ingredients. It takes years of practice to master the balance of rice texture and topping placement. A Nigiri Sushi Machine can replicate the precision of a sushi chef, producing up to 2,500 perfectly shaped rice balls per hour. You can customise size and density, ensuring consistent quality without the labour-intensive process of handcrafting each piece.

How Sushi Robot are Transforming Sushi Production in Restaurants

-

Improving Restaurant Operations

Automated sushi-making technology helps manage production by allowing for the quick and accurate creation of sushi rolls, nigiri, and other varieties. This technology outperforms manual methods, resulting in faster service, reduced customer wait times, and increased customer satisfaction and revenue. Each piece of sushi produced is uniform and shaped, essential for meeting quality standards and customer expectations.

Robotic sushi production boosts efficiency and meets the growing demand for quick service. As diners increasingly seek fast and consistent experiences, automated sushi machines offer a reliable solution.

-

Quality Control and Food Safety

Quality control and hygiene are critical in food preparation. Automated sushi-making machines enhance food safety by adhering to strict certifications and regulations, such as C.E. certification and compliance with Food Standards Australia New Zealand.. This compliance reduces operational risks and builds trust with health inspectors and customers concerned about food safety.

These machines also ensure consistent quality. Accurate cutting and portion control minimise waste and guarantee that every sushi piece meets high standards.

Cultural Implications Between Traditional and Modern Sushi

The introduction of robotic technology in sushi-making highlights a significant clash between tradition and modernity. Sushi has long been viewed as a culinary art form that requires skill, accuracy, and a deep understanding of ingredients. Many traditional sushi chefs spend years perfecting their craft, emphasising the importance of techniques passed down through generations. However, the rise of automated sushi-making brings efficiency and consistency that can challenge these age-old practices.

Restaurants can adapt by respecting sushi tradition and embracing innovation. They can integrate automated technology alongside traditional methods, such as using robots for tasks like rice preparation or rolling, while chefs focus on garnishing and flavour combinations.

Some restaurants have effectively combined technology and tradition. For instance, certain sushi bars use robotic sushi robot for high-volume orders during busy times, while also offering hand-crafted sushi made by skilled chefs. This setup provides customers with both quick, consistent service and the personalised touch of traditional sushi making.

Another example is a sushi chain that showcases its heritage by featuring a "chef's special" menu, where traditional sushi is prepared in front of customers, showcasing the art of sushi-making. At the same time, they use automated machines to fulfil standard orders quickly, ensuring that all customers receive their meals promptly.

Conclusion

The sushi industry is undergoing a significant transformation with the integration of robotic sushi machines, marking a shift towards efficiency and consistency in preparation. While sushi is traditionally revered as an art form, automation enables restaurants to meet growing customer demands without sacrificing quality.

Many establishments successfully blend technology with tradition, using machines for high-volume orders while allowing skilled chefs to create artisanal sushi. This hybrid approach respects the craft of sushi-making while catering to modern diners who value speed and quality.

Sushi Making Made Easy!

Take your sushi preparation to the next level! Get a quote for Sushi Nigiri Robot and streamline your restaurant’s operations!

FAQ

-

How do robotic sushi machines improve restaurant operations?

These machines enable faster service, reduce customer wait times, and increase production capacity, allowing restaurants to meet high demand without compromising quality.

-

Are automated sushi machines safe to use?

Yes, most robotic sushi machines comply with food safety regulations and certifications, ensuring they meet hygiene standards and reduce operational risks.

-

Can automated machines replicate the artistry of traditional sushi-making?

While robotic machines can produce consistent sushi quickly, they often work alongside skilled sushi chefs who add the artistic touch and flavour combinations, blending tradition with technology.